Dynamic Descaler & Aqua Safe is available to order in: I.B.C. (1000 – 1250 ...

• HEAT EXCHANGERS

• BOILERS

• VACUUM PUMPS

• CHILLERS

• CONDENSERS

• OIL COOLERS

• COOLING TOWERS

• WATER PIPING

• HOLDING TANKS

• RESERVOIRS

• HEATING ELEMENTS

Dynamic Descaler is the safe and effective way to remove scale deposits from all types of water cooled and water heated equipment

-

Chillers

-

Compressors

-

Furnaces

-

Quenchers

-

Vacuum Pumps

-

CO2 Generators

-

Heaters

-

Exchangers

-

Rinse Tanks

-

Sterilizers and Washers

-

Dryers

-

Extrudres

-

Kettles

-

Mixers

-

Reactors

-

Scrubbers

-

Vacuum Pumps

-

Condensers

-

Ice Machines

-

Kathabars

-

Refrigeration Equipment

-

Steam Tables

-

Bearings

-

Conveyors

-

Fans

-

Hearth & Vacuum Furnaces

-

Shelters

-

Sprays

-

Exchangers

-

Loop Systems

-

Kathabars

-

Pumps

-

Reactors

-

Stills

-

Sterilizers

-

Chillers

-

Compressors

-

Furnaces

-

Quenchers

-

Vacuum Pumps

-

Bearings

-

Conveyors

-

Filters

-

Presses

-

Process Lines

-

Radiators

-

Calendar Rolls

-

Mill Rolls

-

Caustic Lines

-

Scrubbers

-

Compressors

-

Liquor Tanks

-

Pulverizers

-

Vacuum Pumps

-

Compressors

-

Converters

-

Crackers

-

Exchangers

-

Piping

-

Pumps

-

Banbury Mixers

-

Calendar & Mill Rolls

-

Extruders

-

Injection Moulders

-

Moulds

-

Temperature Control Units

-

Throat Coolers

-

Towers and Tubers

-

Bearings

-

ConCast Units

-

Generators

-

Hearths

-

Spangle Units

-

Furnaces

-

Air Washers

-

Compressors

-

Condensers

-

Exchangers

-

Extruders and Towers

-

Boilers

-

Turbines

-

Transformers

-

Cooling Towers

-

Air Compressors

-

Hydrogen Coolers

-

Lube Oil Heat Exchangers

-

Ball Mills

-

Demisters

-

Evaporators

-

Locomotives

-

Absorption Units

-

Diesel Generators

-

Induction Furnaces

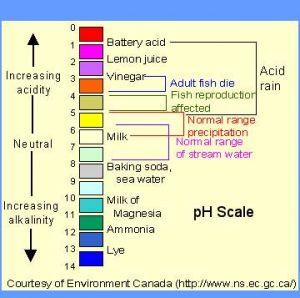

Our descalers pH range is between 0 and 1.5, depending on which product you are using and what type of metal is present in your system.

Our descalers pH range is between 0 and 1.5, depending on which product you are using and what type of metal is present in your system.

There is only one reason for the pH to go up and that is if there is still scale present in your equipment. (Rust or Iron Oxide is different).

If the pH does not increase, your piece of equipment in most cases is clean. (While you are circulating the descaler in your equipment and the pH goes up to 2.5 or around 3 when checked, add more D

descaler to get the pH back down to 1pH or lower. Repeat this process if needed)

Check our “How to use" page for charts on how much Descaler is to be used and for how long. All equipment has a different amount and circulation time period.

When you call and ask about our products we’ll help you understand the difference between mildly corrosive vs. non-corrosive. We care about your machinery and for the safety of your employees. Watch out for non-corrosive claims from other companies. Our Descalers have the best corrosion rates on all types of metals. Compared to all other companies we have the lowest!

Our Descalers are safe on your skin, but this is a chemical that contains acid, so use all precaution to protect yourself and your employees. On our SDS it states to use safety glasses and rubber gloves. We take great pride in the safety of our products and most important we care about your employees. If you have any question please feel free to contact us.

If your water cooled equipment has never been cleaned before, we recommend 100%. After the first cleaning, you can use a 50/50 water mixture. In some cases, you can use even less .

We offer different Descaler formulas because an “all in one” chemical Descaler is not safe on all types of metals. When our customers call to ask information about our Descalers, we always ask is what type of metal is present. It’s a simple yet profound question.

For Example, if an HCL (Hydrochloric Acid) product is used on Stainless Steel, it will over time, penetrate the passivation of the equipment and cause stress cracks.

Please call us to better understand the proper Descaler for your machinery. Do not risk down time by destroying the metal that is present in your water cooling equipment.

WOLT DORN

BILL CARPENTER

ALVARO VIRGEN

-

Read more +

15th March 2019 By admin in Industrial Descaler, Marine Descaler, Uncategorised

Read more +

15th March 2019 By admin in Industrial Descaler, Marine Descaler, Uncategorised

Ordering Dynamic Descaler

-

Read more +

By admin in Industrial Descaler, Marine Descaler, Uncategorised

Read more +

By admin in Industrial Descaler, Marine Descaler, Uncategorised

The Worlds Best Descaling Solution

-

Read more +

12th March 2019 By admin in Industrial Descaler, Marine Descaler, Uncategorised

Read more +

12th March 2019 By admin in Industrial Descaler, Marine Descaler, Uncategorised

Introducing Dynamic Descaler